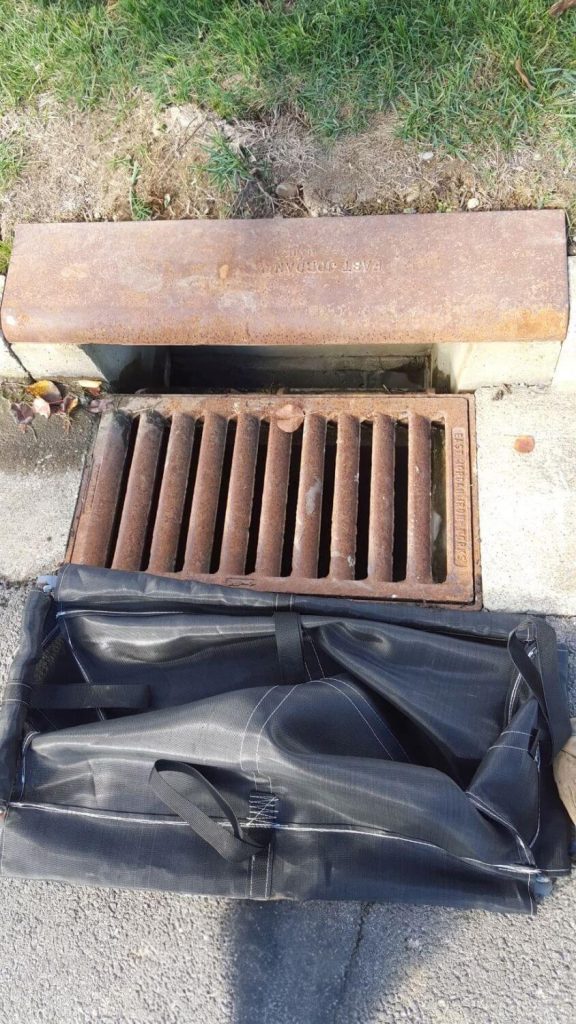

Filter stormwater runoff and protect drain inlets with Inlet Protection BMPs

Whether above-ground or below-grate, Inlet Protection BMPs help prevent sediment, debris, pollutants, and other particles from entering any storm drainage system. Easily and effectively prevent scour and silt concentration in drop or curb inlets, storm drainage systems and receiving channels with MKB Company BMPs.

Advantages

Variety of BMPs fit virtually any storm drain system

Use heavy duty StormCatcher or RockSock for high traffic areas

Filter 20+ common stormwater pollutants with EnviroSoxx and StormExx

Weighted BMPs stay put in concentrated flows without trenching, stakes, or anchors

Prevents street flooding

Easy to install & remove

Products

Applications

Around drain inlets

In front of curb inlets

As curb sediment containment system

Around storm drainage systems

Receiving channels

TYPES OF INLETS

DRAIN INLETS

Drain inlets are located in areas that receive runoff from surrounding lands, often exposed and disturbed soils, and are located at a low point, or in a sump. Inlet protection used around drain inlets (or rain inlet protection) should completely enclose the circumference of the drain and where possible should not be placed on a grade or slope. Inlet protection used around drain inlets should never be the only form of site sediment control and should be accompanied by erosion control/slope stabilization practices, such as compost erosion control blankets or rolled erosion control blankets. Inlet protection should never be placed where they divert runoff flow from the drain inlet, or on top of the inlet, which can cause flooding. Under high runoff and sediment loading conditions placement of 1-2 in (25-50 mm) diameter rock (AASHTO #2) may be placed around the outer circumference of the inlet protection up to ½ the height of the inlet protection. This will help slow runoff velocity as it contacts the inlet protection and will reduce sediment build-up and clogging of the inlet protection.

CURB INLETS

Curb inlets are generally located on paved surfaces and are designed to rapidly drain storm runoff from roadways to prevent flooding that poses a hazard to vehicular traffic. Inlet protection devices should be placed in a manner which intercepts runoff prior to entering the inlet, but does not block or divert runoff from the inlet. To prevent diversion of runoff, inlet protection used around curbs (or curb inlet protection) should be used in low points, or sumps, and minor slopes or grades. Inlet protection should never be placed in or on the curb inlet drain, or placed in a manner that obstructs vehicular traffic. Inlet protection height should be at least 1 in (25 mm) lower than top of curb inlet to allow for overflow into the drain and not over the curb. Maximum sediment removal efficiency occurs when minor ponding exists behind inlet protection but should never lead to flooding.

CURB SEDIMENT CONTAINMENT SYSTEMS

Curb sediment containment systems are used to reduce the sediment and pollutant load flowing to a curb inlet. They are generally placed on paved surfaces perpendicular to runoff flow and should be lower than the height of the curb. Curb sediment containment systems should never cause flooding or be placed where they are a hazard to vehicular traffic. Inlet protection used for curb sediment containment (or curb sediment containment inlet protection) can be placed on a grade but should never be placed directly upslope from curb inlet where it may inadvertently divert runoff from entering curb inlet.

DESIGN SPECIFICATIONS & CADs

We provide FREE access to our Design Manual. Our database includes product specifications, installation guidelines and recommendations, as well as CADs for over 25 applications. Engineers, designers and installers rely on our Design Manual to evaluate our products and find best suitable solutions.